Biodigesters offer an eco-friendly solution to organic waste management, providing renewable energy and nutrient-rich fertilizer.

In this guide, we’ll walk you through the process of constructing a biodigester, from planning and design to testing and commissioning.

Constructing a biodigester offers numerous benefits for both the environment and your household.

By converting organic waste into biogas and fertilizer, biodigesters help reduce dependence on fossil fuels, minimize odors and pathogens, and improve soil fertility and crop yields.

Introduction

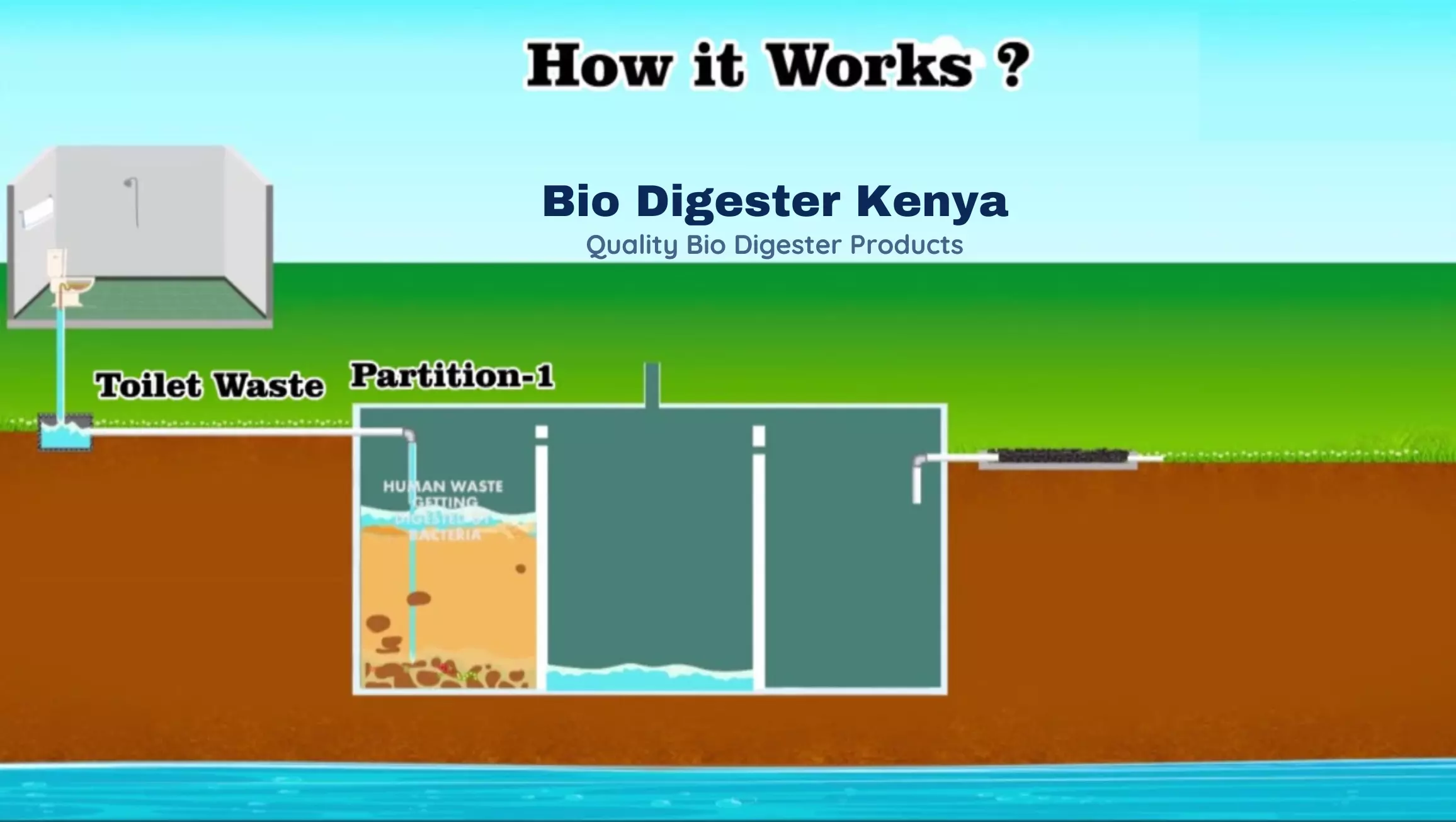

Biodigesters are anaerobic digestion systems that break down organic matter, such as animal manure, food waste, and crop residues, to produce biogas and nutrient-rich effluent.

These systems play a crucial role in sustainable waste management, reducing greenhouse gas emissions and producing valuable resources.

What is a Biodigester?

A biodigester is an innovative and eco-friendly waste management solution that converts organic waste into biogas and nutrient-rich fertilizer.

It is a sealed, underground tank that facilitates the natural process of anaerobic digestion, breaking down biodegradable materials in an oxygen-free environment.

Benefits of Using a Biodigester

Biodigesters offer numerous advantages, including:

- Renewable energy production (biogas)

- Reduction of greenhouse gas emissions

- Nutrient-rich fertilizer for agricultural purposes

- Improved sanitation and waste management

- Cost-effective and sustainable solution

Why Choose Biodigester Kenya?

Bio Digester Kenya is a leading provider of bio digester solutions in Kenya.

We specialize in designing, installing, and maintaining high-quality biodigesters for both residential and commercial properties.

Our team of experts ensures that your biodigester is tailored to your specific needs, delivering efficient waste management and renewable energy production.

Understanding the Basics

The Science Behind Biodigesters

Biodigesters harness the power of anaerobic digestion, a natural process where microorganisms break down organic matter in the absence of oxygen.

This process produces biogas, primarily composed of methane and carbon dioxide, which can be used for cooking, heating, or generating electricity.

Types of Biodigesters

There are various types of biodigesters, each designed to suit different waste streams and environments. Some common types include:

- Continuous Flow Biodigesters

- Batch Biodigesters

- Plug Flow Biodigesters

- Covered Lagoon Biodigesters

Materials Needed

To construct a biodigester, you’ll need the following materials:

- Concrete or plastic tanks

- Inlet and outlet pipes

- Gas collection system (e.g., gas storage tank, piping)

- Biodigester enzymes (more on this later)

- Gravel, sand, and other construction materials

Planning and Site Preparation

Choosing the Right Location

Selecting the appropriate location for your biodigester is crucial.

Consider factors such as proximity to the waste source, distance from water sources, soil conditions, and accessibility for maintenance.

Obtaining Necessary Permits

Before construction, ensure you obtain all necessary permits and approvals from local authorities.

This may include building permits, environmental impact assessments, and any other relevant documentation.

Excavation and Pit Preparation

Once the location is determined, excavate the area where the bio digester will be installed.

Prepare the pit according to the specific design and size requirements, ensuring proper drainage and stability.

Construction Process

Building the Foundation

Construct a solid foundation for the biodigester tank.

This may involve laying a concrete slab or preparing a stable base using gravel and compacted soil.

Constructing the Digester Tank

The biodigester tank can be constructed using various materials, such as concrete, fiberglass, or plastic.

Follow the manufacturer’s instructions or hire a professional contractor to ensure proper installation.

Installing the Inlet and Outlet Pipes

Install the inlet and outlet pipes to facilitate the flow of waste into the biodigester and the release of digestate (the nutrient-rich byproduct) from the system.

Setting up the Gas Collection System

Set up the gas collection system, which typically includes a gas storage tank and piping to transport the biogas to its intended use (e.g., cooking, heating, or electricity generation).

Biodigester Enzymes and Their Role

What are Biodigester Enzymes?

Biodigester enzymes are specialized biological catalysts that aid in the breakdown of organic matter within the biodigester.

They play a crucial role in accelerating the anaerobic digestion process, improving biogas production, and ensuring efficient waste management.

Importance of Biodigester Enzymes

Using biodigester enzymes offers several benefits, including:

- Increased biogas yield

- Faster decomposition of organic waste

- Improved biodigester efficiency and performance

- Reduced maintenance requirements

- Prolonged lifespan of the bio digester

Where to Purchase Biodigester Enzymes

At Bio Digester Kenya, we offer high-quality biodigester enzymes tailored specifically for our biodigester systems.

Our enzymes are designed to optimize the performance of your biodigester, ensuring maximum biogas production and efficient waste management.

Maintenance and Troubleshooting

Regular Maintenance Tasks

To ensure the longevity and optimal performance of your biodigester, regular maintenance is essential.

This may include tasks such as:

- Monitoring pH levels and temperature

- Checking for blockages or leaks

- Cleaning the gas collection system

- Removing excess sludge or digestate

Common Issues and Solutions

Like any system, biodigesters may encounter issues from time to time.

Some common problems and their solutions include:

- Low biogas production: Check the pH levels, temperature, and feed rate. Consider adding biodigester enzymes or adjusting the feedstock composition.

- Odor issues: Ensure proper sealing and maintenance of the biodigester. Consider adding odor control agents or adjusting the feedstock composition.

- Clogging: Implement regular maintenance routines and check for blockages in the inlet and outlet pipes.

Safety Precautions

When working with biodigesters, it’s essential to follow proper safety precautions, such as:

- Wearing appropriate personal protective equipment (PPE)

- Ensuring proper ventilation and avoiding confined spaces

- Handling biogas with caution, as it is flammable

Conclusion

Benefits of Using Biodigester Kenya’s Services

By choosing Bio Digester Kenya for your biodigester needs, you’ll benefit from our expertise, high-quality products, and exceptional customer service.

Our team will guide you through the entire process, from design and installation to maintenance and troubleshooting, ensuring a seamless and efficient waste management solution.

Take the first step towards a sustainable future by contacting Bio Digester Kenya today.

Our team will be happy to provide you with a personalized consultation and quote, tailored to your specific needs.

Embrace the benefits of biodigesters and join the growing community of environmentally conscious individuals and businesses in Kenya.

FAQs

- How long does it take for a biodigester to start producing biogas? The time required for a biodigester to start producing biogas can vary depending on factors such as the type of feedstock, temperature, and the presence of biodigester enzymes.

On average, it may take several weeks to several months for the digester to reach optimal biogas production levels. - Can a biodigester handle all types of organic waste? Biodigesters are designed to handle various types of organic waste, including food waste, animal manure, and agricultural residues.

However, it’s important to avoid introducing non-biodegradable materials or toxic substances, as they can disrupt the anaerobic digestion process. - How often does a biodigester need maintenance? The frequency of maintenance required for a biodigester depends on its size, the amount of waste processed, and the specific design.

Generally, routine maintenance tasks such as checking pH levels, inspecting for leaks, and removing excess sludge should be performed every few months.

More comprehensive maintenance may be required annually or as recommended by the manufacturer or installer. - Is the biogas produced by a biodigester safe for use? The biogas produced by a biodigester is primarily composed of methane and carbon dioxide, which are flammable gases.

While biogas is generally safe for use in cooking, heating, and electricity generation, proper precautions must be taken to ensure safe handling, storage, and use.

It’s recommended to follow the manufacturer’s instructions and local regulations regarding biogas utilization. - Can a biodigester be used in urban areas? Yes, biodigesters can be an effective waste management solution in urban areas, both for residential and commercial properties.

They are particularly beneficial in areas with limited access to traditional waste management infrastructure or where there is a need to reduce the environmental impact of organic waste disposal.